A Strong Plan Drives a Strong Study

I’ve seen and used many different templates to document a Plan-Do-Study-Act (PDSA) cycle. The templates range from those that have just a bit of guidance to those that ask for lots of details.

What are the essential ingredients to help build a useful learning cycle?

Not every learning experience qualifies as a PDSA cycle

I’ve written several posts that quote a definition of a PDSA cycle from my colleagues at Associates in Process Improvement (API):

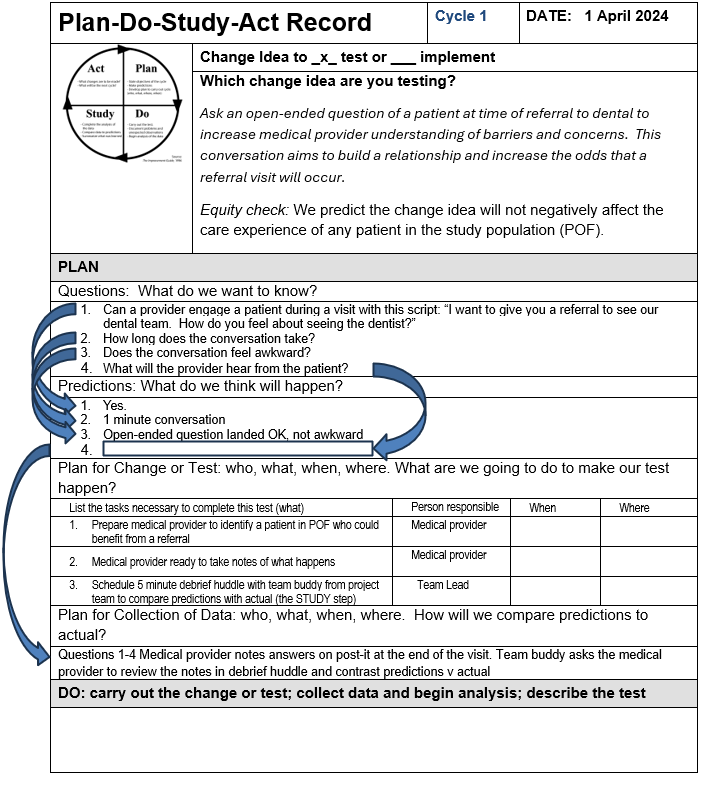

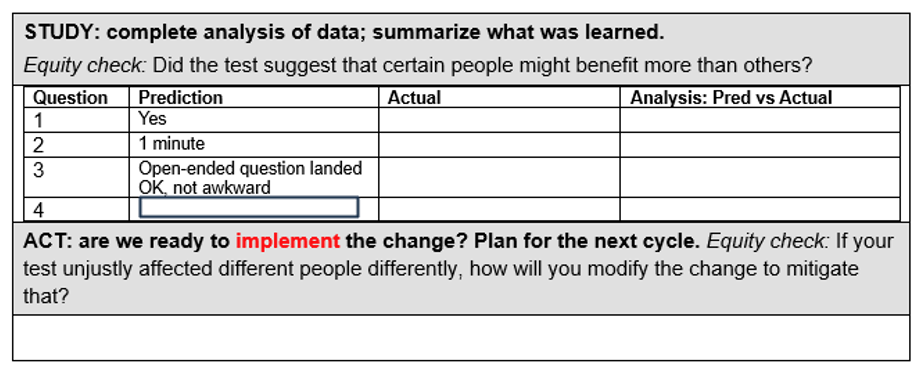

“To be considered a PDSA Cycle, four aspects of the activity should be easily identifiable:

1. Plan: the learning opportunity, test or implementation was planned and included:

• Questions to be answered

• Predictions of the answers to the questions

• Plan for collection of the data to answer the questions

2. Do: the plan was attempted. Observations are made and recorded, including those things that were not part of the plan.

3. Study: time was set aside to compare the data with the predictions and study the results.

4. Act: action was rationally based on what was learned.”

--G. Langley et al. (2009), The Improvement Guide, 2nd edition, Jossey-Bass: San Francisco, pp. 98-99

Langley and his co-authors emphasize that the Plan step must include three inquiry ingredients, not just how to schedule and carry out the observation, test or implementation.

The Question-Prediction-Data Collection Cascade

In a recent project, Dr. Pam Lee has started to investigate red bag waste management at Harbor UCLA Medical Center in Los Angeles.

A few weeks ago, Dr. Lee audited one day’s waste from one unit. The audit revealed a lot of opportunities to reduce costs and environmental impact. The audit required careful safety precautions and a couple of hours of labor.

As a next step in her investigation, Dr. Lee wants a low-cost and rapid measurement of red bag waste weights associated with the unit she audited. Weight records are available but only aggregated across many of the medical center‘s units. Working with two colleagues, Dr. Lee decided to get a scale and try out a weighing method. Could they use a digital scale and a smart phone to capture a bag’s weight? If the one-day trial of weighing works, the team will use the weighing method for several days to get a baseline before they test changes to workflow aimed to improve red bag waste management. The weights before and after the changes will help everyone judge the impact of the changes.

Here are ingredients from the Plan step for the first weighing test. Dr. Lee also shared what happened.

Why Bother with PDSA?

Learning occurs naturally. You and I accumulate experience and modify our understanding and behavior based on what we’ve seen and done. Our minds use shortcuts (heuristics) to navigate hundreds of day-to-day decisions. The short-cuts are fast (good) but may mislead us (bad) when we’re working in novel situations.

Ahead of the investigation of weighing bags of waste, I encouraged Dr Lee to strengthen the Plan Step, linking each question to a prediction and outlining how to get data to answer the question. Is that too much effort for such a simple test?

Slowing down the PDSA discipline in novel situations yields an immediate benefit and builds skill for future applications.

The immediate benefit: You make explicit what you are trying to learn right now as you move from thinking to action. If you’re working with other people, stating and writing out the steps makes it easier to communicate intention and results. At the same time, you are building shared understanding among members of your team.

The long-term benefit: Practicing the PDSA discipline makes the PDSA steps more and more automatic. You can quickly run through the steps in new applications and under stress. You’re ready to learn efficiently and effectively in a range of situations.

Acknowledgment

Thanks to Dr. Pam Lee, Harbor UCLA Medical Center, for permission to share her project work in this post. Dr. Lee and I are working together in the Safety Net Decarbonizing Care Collaborative, organized by the Institute for Healthcare Improvement and funded by The Commonwealth Fund.

Links to several posts discussing PDSA

https://www.iecodesign.com/blog/2023/5/22/explore-before-exploit

https://www.iecodesign.com/blog/2022/4/6/learning-pits-productive-failure-and-plan-do-study-act

https://www.iecodesign.com/blog/2021/5/12/thinking-fast-and-slow-revisited

https://www.iecodesign.com/blog/2018/4/17/pdsa-forms-and-pdsa-practice

https://www.iecodesign.com/blog/2016/9/6/predictions-and-the-problem-of-hindsight-bias